Chainsaw sharpening angle charts are essential tools for maintaining the efficiency and longevity of your chainsaw. Understanding the different angles and their applications can help you achieve optimal cutting performance and extend the life of your chain.

In this guide, we will delve into the types of chainsaw sharpening angles, their advantages and disadvantages, and the factors that influence the selection of the right angle. We will also provide practical tips on measuring and setting sharpening angles and share best practices for maintaining a sharp chainsaw.

Types of Chainsaw Sharpening Angles: Chainsaw Sharpening Angle Chart

The angle at which you sharpen your chainsaw chain has a significant impact on its cutting efficiency and lifespan. There are several common chainsaw sharpening angles, each with its own advantages and purposes.

Top Plate Angle

The top plate angle refers to the angle between the top of the cutting tooth and the horizontal plane. Common top plate angles range from 25 to 35 degrees. A lower angle (e.g., 25 degrees) provides a more aggressive cut but may dull faster.

The chainsaw sharpening angle chart provides guidance for achieving optimal cutting performance. By contrast, if you’re looking for a different kind of chart, check out this dmc color chart with names and numbers . Returning to chainsaw sharpening, remember that the correct angle ensures efficient cutting and extends the life of your chainsaw.

A higher angle (e.g., 35 degrees) provides a smoother cut but may be less efficient.

Side Plate Angle, Chainsaw sharpening angle chart

The side plate angle refers to the angle between the side of the cutting tooth and the horizontal plane. Common side plate angles range from 50 to 60 degrees. A lower angle (e.g., 50 degrees) provides a cleaner cut but may be more susceptible to kickback.

A higher angle (e.g., 60 degrees) provides a more aggressive cut but may produce more sawdust.

Depth Gauge Angle

The depth gauge angle refers to the angle between the depth gauge and the horizontal plane. The depth gauge determines how deep the chain cuts into the wood. Common depth gauge angles range from 60 to 70 degrees. A lower angle (e.g.,

60 degrees) provides a deeper cut but may increase the risk of kickback. A higher angle (e.g., 70 degrees) provides a shallower cut but may reduce the efficiency of the chain.

Chainsaw Sharpening Angle Chart

Selecting the appropriate sharpening angle for your chainsaw is crucial for optimizing cutting performance and prolonging the lifespan of your chain. This comprehensive chart provides a detailed overview of various tooth angles, their applications, and their advantages and disadvantages.

It’s important to note that the optimal sharpening angle may vary depending on factors such as the type of wood being cut, the condition of the chain, and personal preferences. By understanding the characteristics of each angle, you can make informed decisions to achieve the desired cutting results.

Chainsaw Sharpening Angle Chart

| Tooth Type | Tooth Angle | Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Chisel | 30-35° | General-purpose cutting | Aggressive cutting action, high efficiency | Requires more frequent sharpening, prone to kickback |

| Semi-Chisel | 25-30° | All-around cutting, less kickback | Good balance of sharpness and durability, reduces kickback | Less aggressive than chisel, may require more sharpening |

| Micro-Chisel | 10-15° | Fine finishing, crosscutting | Produces a smooth, clean cut, minimizes kickback | Not as aggressive as chisel or semi-chisel, may dull quickly |

| Square-Ground | 0° | Ripping, cutting with the grain | Very efficient for cutting straight lines, low kickback | Not suitable for crosscutting, requires frequent sharpening |

| Hook | 40-50° | Aggressive cutting, plunge cutting | Rapid cutting speed, good for large trees | Prone to kickback, requires more sharpening |

Factors Influencing Sharpening Angle Selection

The optimal sharpening angle for a chainsaw chain depends on several key factors, including chain type, wood species, and cutting conditions.

Chain Type

The type of chainsaw chain you are using will influence the ideal sharpening angle. Chains with smaller cutter teeth, such as those designed for cutting softwood, typically require a sharper angle (around 25-30 degrees) to achieve optimal performance. Chains with larger cutter teeth, such as those used for cutting hardwood, may benefit from a wider angle (around 35-45 degrees) to provide greater durability and resistance to wear.

Wood Species

The type of wood you are cutting can also impact the sharpening angle. Softwoods, such as pine and cedar, have a lower density and require a sharper angle (around 25-30 degrees) to create clean, precise cuts. Hardwoods, such as oak and maple, have a higher density and may require a wider angle (around 35-45 degrees) to penetrate the wood effectively.

Cutting Conditions

The cutting conditions you encounter will also influence the sharpening angle. If you are cutting frozen or wet wood, a wider angle (around 35-45 degrees) may be necessary to provide greater cutting power and prevent the chain from bogging down.

Sharpening your chainsaw correctly is crucial for optimal performance. Check out our comprehensive chainsaw sharpening angle chart for precise angles. If you’re planning a night out, take a look at the venue at thunder valley seating chart to find the best seats for your next concert or show.

Remember, proper chainsaw sharpening ensures a smooth and efficient cutting experience.

If you are cutting dry, seasoned wood, a sharper angle (around 25-30 degrees) may be more appropriate to create smooth, clean cuts.

Methods for Measuring and Setting Sharpening Angles

Accurately measuring and setting the sharpening angle of a chainsaw is crucial for optimal cutting performance. Various methods can be employed to achieve precise angle adjustments.

Using Angle Gauges

Angle gauges are specialized tools designed to measure and set specific angles. They typically consist of a protractor-like scale with a magnetic base that attaches to the chainsaw chain. By aligning the gauge with the cutting teeth, you can easily determine the current angle and adjust it accordingly.

Using Protractors

Protractors, commonly used in geometry, can also be employed to measure sharpening angles. Place the protractor’s base against the chainsaw chain and align the zero mark with the cutting edge. The angle between the cutting edge and the protractor’s base represents the sharpening angle.

Other Measuring Tools

Other tools, such as digital angle finders or inclinometers, can also be used to measure sharpening angles. These tools typically provide precise measurements and may be more suitable for specific applications or user preferences.

Step-by-Step Guide for Setting Sharpening Angles

- Secure the chainsaw chain firmly in a vise or on a stable surface.

- Choose the desired sharpening angle based on the type of chainsaw and cutting application.

- Select an appropriate measuring tool and align it with the cutting edge of the tooth.

- Adjust the angle until it matches the desired setting.

- Lock or tighten the measuring tool to secure the angle.

Best Practices for Chainsaw Sharpening

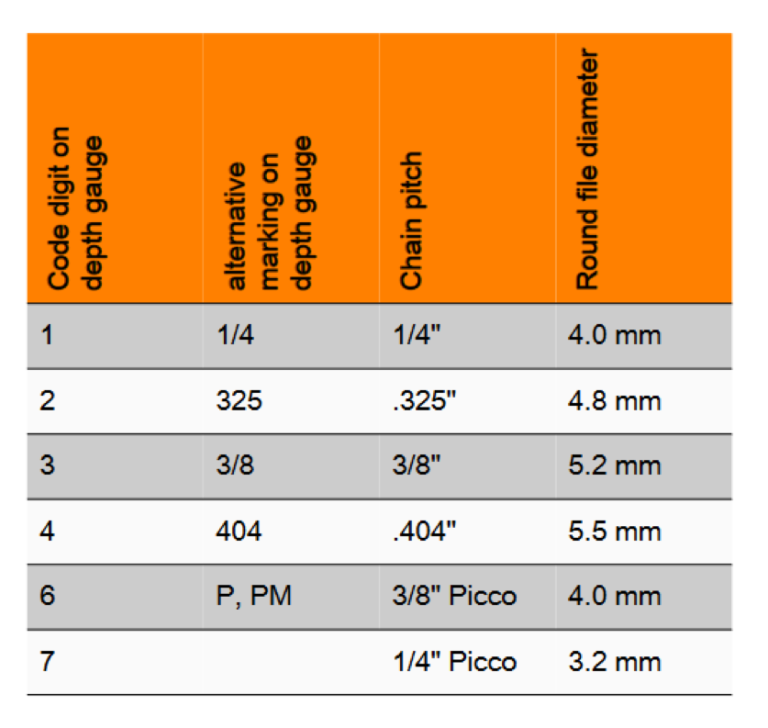

Regular chainsaw sharpening is essential for maintaining optimal cutting performance and safety. Here are some best practices to follow:Sharpen frequently: A sharp chain cuts more efficiently, reduces strain on the saw, and prevents kickback. Aim to sharpen the chain every 4-8 hours of use, or more often if you’re cutting hard or dirty wood.Use

proper filing techniques: Use a round file that matches the size of the cutter teeth. Hold the file perpendicular to the bar and file from the inside of the tooth out. File at a consistent angle and apply even pressure to maintain a sharp edge.Invest

in quality sharpening tools: A good-quality round file and a file guide will ensure accurate and consistent sharpening. Avoid using cheap or worn-out files, as they can damage the chain and affect cutting performance.Avoid common mistakes: Over-sharpening can weaken the teeth and reduce their lifespan.

Avoid filing too much off the teeth or filing at an incorrect angle. Also, ensure the chain is tensioned properly before sharpening to prevent damage.

Our website has become a go-to destination for people who want to create personalized calendars that meet their unique needs. We offer a wide range of customization options, including the ability to add your own images, logos, and branding. Our users appreciate the flexibility and versatility of our calendars, which can be used for a variety of purposes, including personal, educational, and business use.