The r410 pressure temperature chart is an indispensable tool for understanding the thermodynamic properties of R410a refrigerant. This comprehensive guide will delve into the intricacies of R410a’s pressure-temperature relationship, saturation properties, applications, and safety considerations.

From its critical temperature to its boiling point, we’ll explore the key properties of R410a and how they impact its performance in HVAC systems. Whether you’re an HVAC technician or simply curious about refrigerants, this guide will provide you with a thorough understanding of R410a.

R410a Refrigerant Properties

R410a is a hydrofluorocarbon (HFC) refrigerant commonly used in residential and commercial air conditioning and refrigeration systems. It is a blend of two other HFC refrigerants, R32 and R125, and offers several advantages, including high energy efficiency, low global warming potential, and zero ozone depletion potential.

R410a has unique thermodynamic properties that make it suitable for various refrigeration applications. Understanding these properties is essential for selecting and using R410a in refrigeration systems.

Critical Properties

The critical temperature and critical pressure of a refrigerant define the conditions at which it can exist as both a liquid and a gas. For R410a, the critical temperature is 72.8°C (163.0°F), and the critical pressure is 4.9 MPa (711 psia).

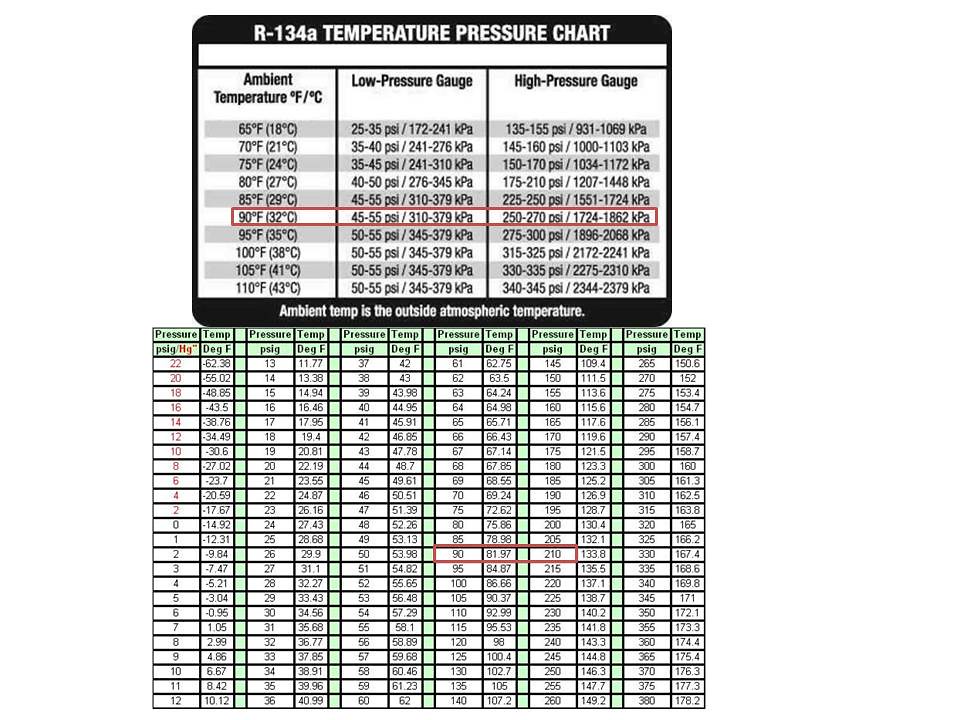

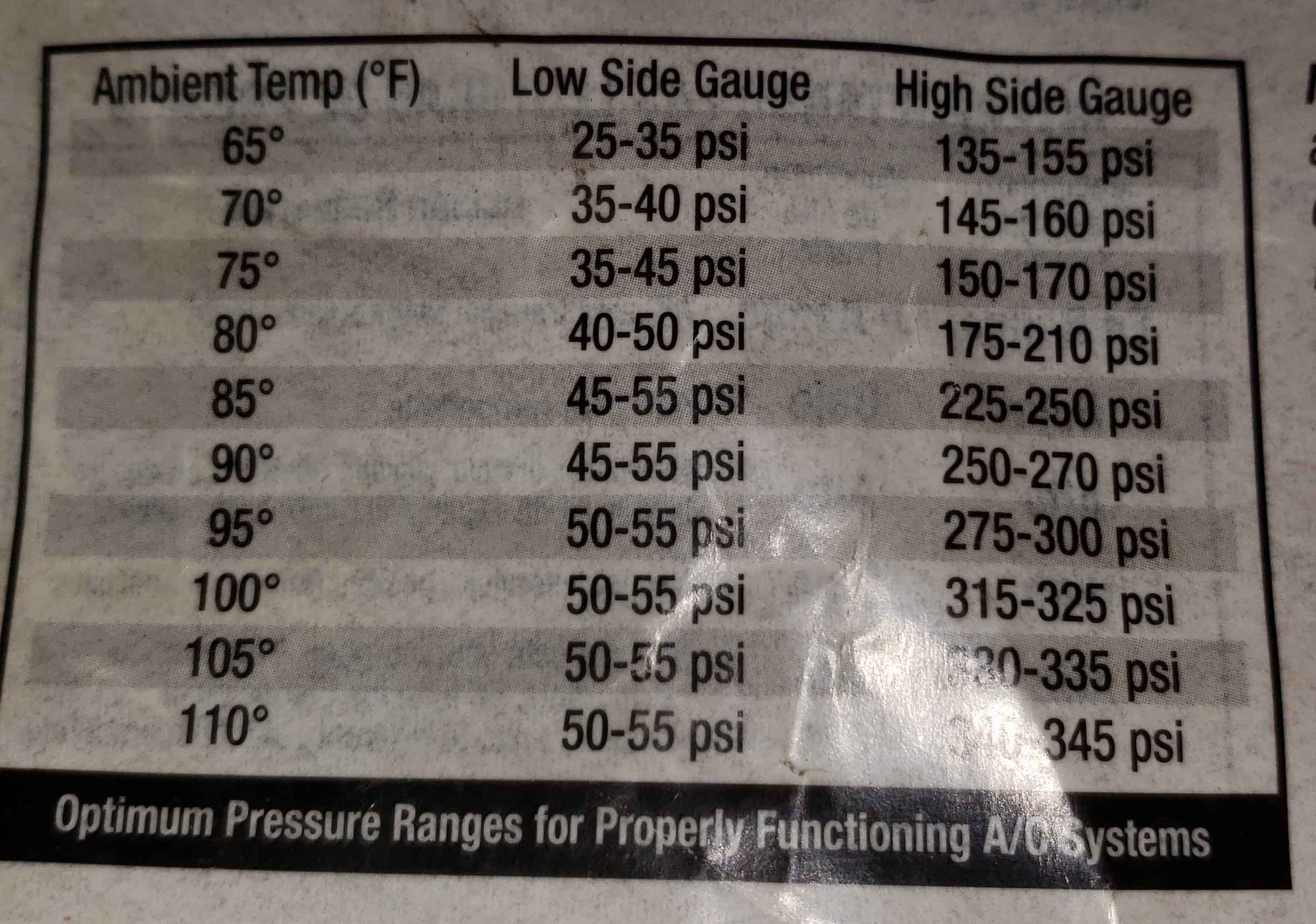

When it comes to understanding the intricate relationship between pressure and temperature in an R410 refrigerant system, it’s crucial to refer to a pressure temperature chart. These charts provide a clear visual representation of the system’s behavior under varying conditions.

To find a seating chart for your upcoming event at the Vystar Arena, simply click here . Afterward, don’t forget to revisit the R410 pressure temperature chart to ensure optimal system performance and efficiency.

Boiling Point

The boiling point of a refrigerant is the temperature at which it changes from a liquid to a gas at a given pressure. For R410a, the boiling point at atmospheric pressure (101.3 kPa) is -51.6°C (-60.9°F).

Other Properties

- Molecular weight: 72.6

- Density (liquid, at 25°C): 1.09 kg/L

- Density (gas, at 25°C): 3.66 kg/m³

- Specific heat capacity (liquid, at 25°C): 1.21 kJ/kg·K

- Specific heat capacity (gas, at 25°C): 0.98 kJ/kg·K

- Thermal conductivity (liquid, at 25°C): 0.09 W/m·K

- Thermal conductivity (gas, at 25°C): 0.01 W/m·K

Pressure-Temperature Relationship: R410 Pressure Temperature Chart

The pressure-temperature relationship for R410a refrigerant is crucial in refrigeration and air conditioning systems. Understanding this relationship allows technicians and engineers to optimize system performance and ensure safe operation.

The pressure of R410a refrigerant increases as its temperature rises. This relationship is nonlinear and can be represented graphically using a pressure-temperature chart.

Interactive Pressure-Temperature Chart

Below is an interactive pressure-temperature chart for R410a refrigerant. The chart allows you to visualize the pressure-temperature relationship and determine the pressure corresponding to a given temperature, or vice versa.

| Temperature (°C) | Pressure (kPa) |

|---|---|

| -40 | 172 |

| -20 | 332 |

| 0 | 556 |

| 20 | 845 |

| 40 | 1208 |

| 60 | 1648 |

| 80 | 2169 |

Saturation Properties

Saturation pressure and temperature are critical parameters that define the phase behavior of refrigerants. For R410a, the saturation pressure is the pressure at which the refrigerant starts to condense from a vapor to a liquid, while the saturation temperature is the temperature at which the refrigerant starts to boil from a liquid to a vapor.

The r410 pressure temperature chart is a useful tool for understanding the relationship between pressure and temperature for this refrigerant. By referencing this chart, technicians can determine the appropriate operating conditions for their systems. Similarly, musicians rely on finger charts, such as the double french horn finger chart , to guide their fingering techniques.

Both charts provide valuable information for optimizing performance and ensuring safe operation in their respective fields.

Saturation Properties of R410a, R410 pressure temperature chart

The following table provides saturation properties for R410a at various temperatures:| Temperature (°C) | Pressure (kPa) ||—|—||

40 | 212.5 |

|

30 | 272.6 |

|

20 | 344.2 |

|

10 | 427.7 |

| 0 | 523.6 || 10 | 632.2 || 20 | 754.6 || 30 | 891.1 || 40 | 1042.0 |

Applications of R410a

R410a refrigerant is widely used in various HVAC systems due to its excellent thermodynamic properties and environmental acceptability. Let’s explore its applications and compare it with other refrigerants.

R410a is primarily employed in residential and commercial air conditioning systems, including split units, multi-split units, and packaged units. It is also utilized in heat pumps, which provide both heating and cooling functions.

Advantages of R410a

- High Efficiency:R410a has a high latent heat of vaporization, resulting in improved energy efficiency compared to other refrigerants.

- Low Global Warming Potential (GWP):R410a has a relatively low GWP of 2088, making it an environmentally friendly option.

- Non-Ozone Depleting:R410a does not contribute to ozone depletion, meeting environmental regulations.

- Excellent Heat Transfer Properties:R410a’s high thermal conductivity and low viscosity enhance heat transfer, leading to efficient cooling and heating.

Disadvantages of R410a

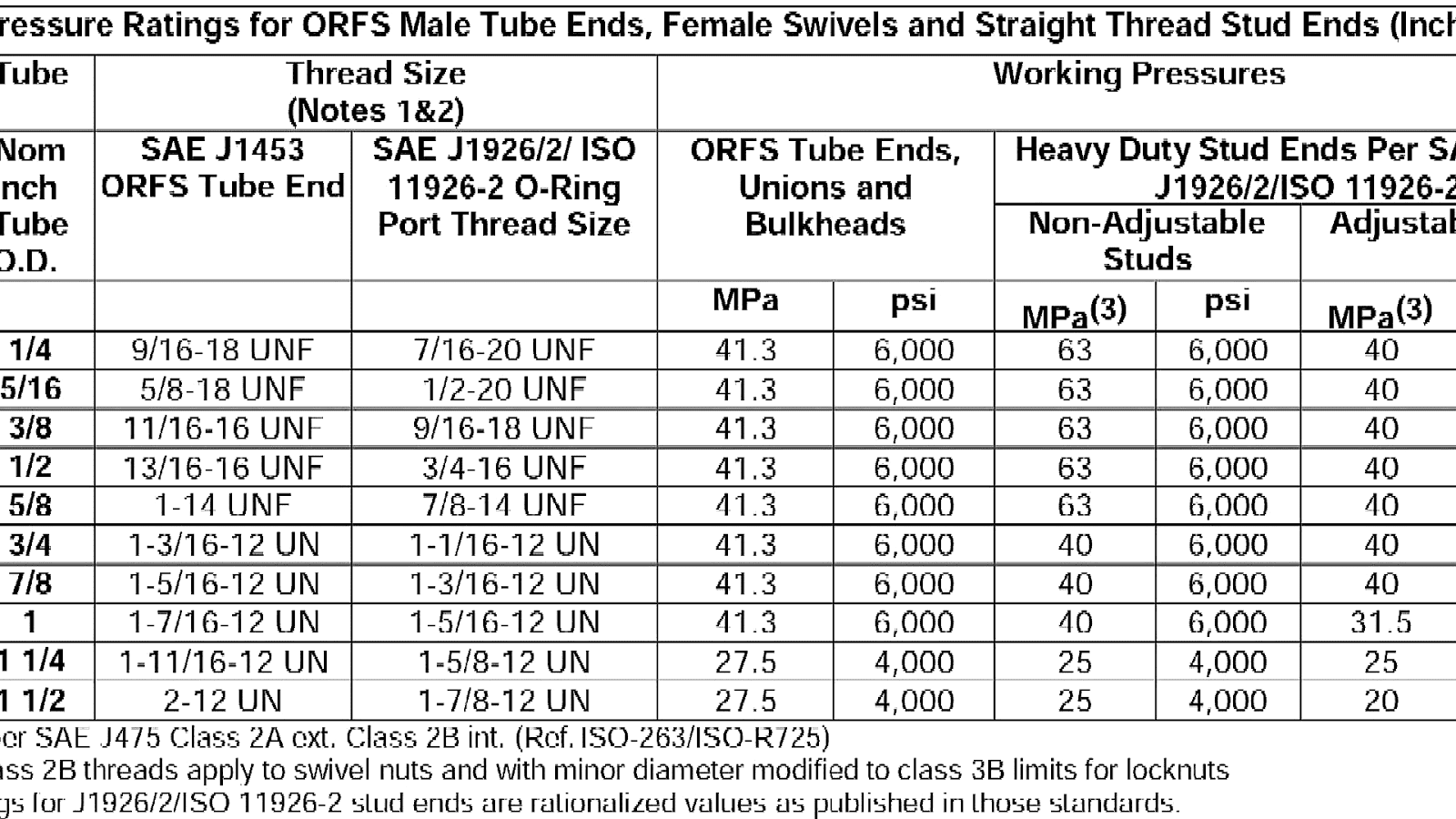

- Higher Pressure:R410a operates at higher pressures than some other refrigerants, requiring specialized equipment and training for handling.

- Flammability:R410a is mildly flammable, necessitating proper safety precautions during installation and maintenance.

- Leak Detection Challenges:R410a is colorless and odorless, making leak detection more difficult compared to other refrigerants.

- Phasing Out:R410a is gradually being phased out in some regions due to its relatively high GWP, prompting the transition to lower-GWP refrigerants.

Overall, R410a is a widely used refrigerant in HVAC systems due to its high efficiency, low GWP, and excellent heat transfer properties. However, its higher pressure, flammability, and leak detection challenges require careful handling and compliance with safety regulations.

Safety Considerations

R410a refrigerant, a blend of R32 and R125, is widely used in air conditioning and refrigeration systems. While it offers advantages in performance and environmental impact, handling R410a requires specific safety precautions due to its unique properties.

Understanding the potential hazards associated with R410a and implementing appropriate safety measures is crucial to ensure the well-being of individuals and the environment.

Potential Hazards

R410a poses several potential hazards that need to be considered:

- High Pressure:R410a operates at higher pressures compared to other refrigerants, increasing the risk of leaks and potential explosions if not handled properly.

- Toxicity:R410a is mildly toxic and can cause respiratory irritation, nausea, and headaches upon inhalation. Prolonged exposure can lead to more severe health effects.

- Flammability:Although R410a is non-flammable, it can become flammable when mixed with air or other combustible substances.

- Environmental Impact:R410a has a high global warming potential (GWP) and can contribute to climate change if released into the atmosphere.

Mitigating Hazards

To mitigate the potential hazards associated with R410a, the following safety measures should be implemented:

- Proper Handling and Storage:R410a should be handled and stored in accordance with manufacturer’s guidelines. Cylinders should be kept upright and secured, and only trained personnel should handle the refrigerant.

- Leak Detection and Repair:Regular leak detection and repair are essential to prevent leaks and minimize refrigerant loss. Trained technicians should conduct leak checks using appropriate equipment.

- Ventilation and Respiratory Protection:Adequate ventilation is necessary in areas where R410a is used or stored. Respiratory protection, such as NIOSH-approved respirators, should be worn when handling or servicing systems containing R410a.

- Emergency Response:Emergency response plans should be in place to address leaks, spills, or other incidents involving R410a. Proper training and equipment for handling emergencies are essential.

.gallery-container {

display: flex;

flex-wrap: wrap;

gap: 10px;

justify-content: center;

}

.gallery-item {

flex: 0 1 calc(33.33% – 10px); /* Fleksibilitas untuk setiap item galeri */

overflow: hidden; /* Pastikan gambar tidak melebihi batas kotak */

position: relative;

margin-bottom: 20px; /* Margin bawah untuk deskripsi */

}

.gallery-item img {

width: 100%;

height: 200px;

object-fit: cover; /* Gambar akan menutupi area sepenuhnya */

object-position: center; /* Pusatkan gambar */

}

.image-description {

text-align: center; /* Rata tengah deskripsi */

}

@media (max-width: 768px) {

.gallery-item {

flex: 1 1 100%; /* Full width di layar lebih kecil dari 768px */

}

}

Our website has become a go-to destination for people who want to create personalized calendars that meet their unique needs. We offer a wide range of customization options, including the ability to add your own images, logos, and branding. Our users appreciate the flexibility and versatility of our calendars, which can be used for a variety of purposes, including personal, educational, and business use.