Step into the realm of precision cutting with the Victor Cutting Tip Chart, your indispensable companion for mastering the art of metal fabrication. This comprehensive guide unveils the secrets of selecting the perfect cutting tip for every job, ensuring flawless results and unparalleled efficiency.

Delve into the intricacies of cutting tip types, unravel the significance of cutting parameters, and navigate the complexities of safety considerations. With expert insights and practical troubleshooting tips, this chart empowers you to conquer any cutting challenge with confidence.

Cutting Tip Chart Overview

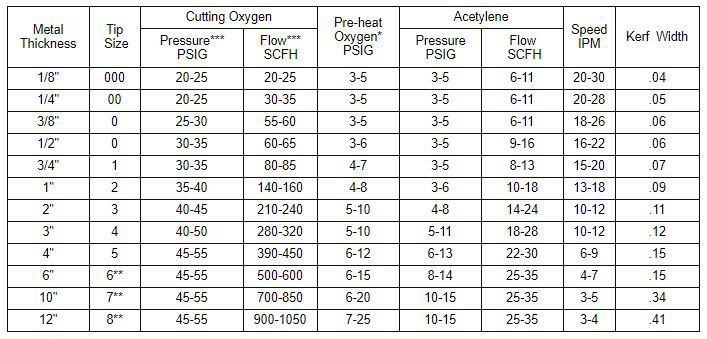

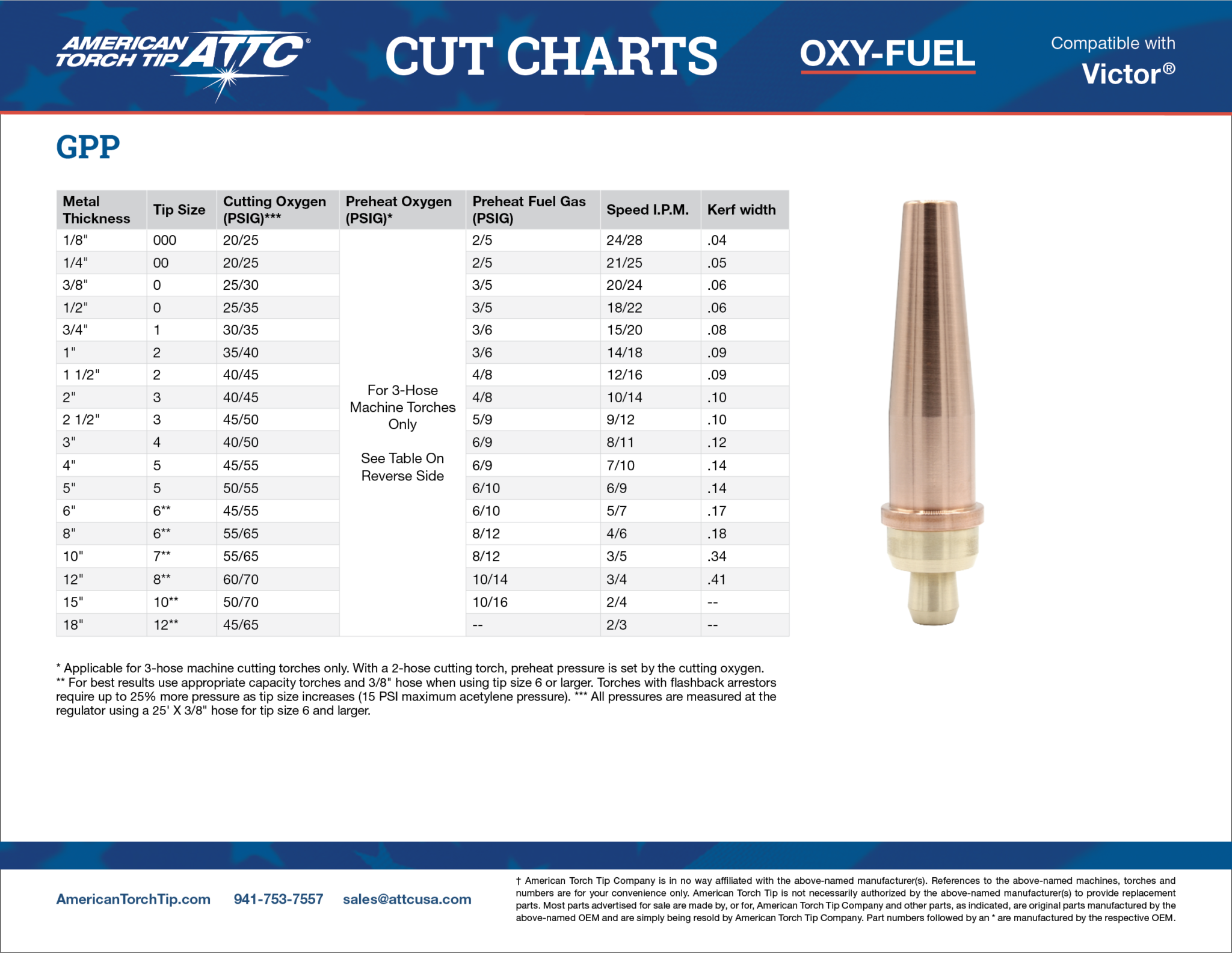

A victor cutting tip chart serves as a comprehensive guide that provides essential information regarding the selection and utilization of cutting tips in various industrial applications. It enables professionals to make informed decisions when choosing the most suitable cutting tip for their specific requirements, ensuring optimal performance and safety during cutting operations.Industries

that commonly utilize cutting tip charts include metal fabrication, construction, and automotive repair. These charts provide crucial details such as the cutting tip size, fuel gas type, oxygen pressure, and cutting capacity, which are essential for achieving precise and efficient cuts in different materials.

When you’re looking for the right victor cutting tip chart, it’s important to consider the material you’ll be cutting. For example, if you’ll be cutting metal, you’ll need a tip that’s specifically designed for that purpose. Once you’ve found the right tip, you can consult the palace theater albany seating chart to determine the best cutting speed and feed rate.

With the right tip and settings, you’ll be able to cut through any material with ease.

Key Elements and Information

A typical cutting tip chart includes several key elements and information:

-*Cutting Tip Size

The size of the cutting tip, typically measured in numbers or letters, determines the thickness of the material that can be cut.

-*Fuel Gas Type

The type of fuel gas used, such as acetylene, propane, or natural gas, influences the cutting performance and flame characteristics.

-*Oxygen Pressure

The recommended oxygen pressure for the specific cutting tip is crucial for achieving the desired cutting speed and quality.

-*Cutting Capacity

The maximum thickness of material that can be cut effectively with the given cutting tip and fuel gas combination.

Types of Cutting Tips

Cutting tips are specialized tools used in plasma cutting, each designed for specific applications and materials. Understanding the different types of cutting tips and their characteristics is crucial for optimizing cutting performance and achieving desired results.

Cutting Tip Materials

Cutting tips are primarily made of two materials:

- Copper:Copper tips are durable and provide excellent heat dissipation, making them suitable for high-speed cutting and thicker materials.

- Hafnium:Hafnium tips are highly resistant to wear and erosion, making them ideal for cutting thin materials and intricate shapes.

Cutting Tip Designs

Cutting tips come in various designs, each with unique characteristics:

- Standard Tips:These tips have a simple cylindrical shape and are commonly used for general-purpose cutting.

- Extended Tips:Extended tips protrude further from the torch, providing better visibility and access to hard-to-reach areas.

- Shielded Tips:Shielded tips have a protective shield that surrounds the electrode, reducing arc wander and improving cut quality.

- Swirl Tips:Swirl tips create a swirling gas flow, resulting in a more concentrated and focused plasma arc for precision cutting.

Applications

The choice of cutting tip depends on the specific application and material being cut:

- Copper tipsare ideal for cutting thick metals, such as steel and stainless steel, at high speeds.

- Hafnium tipsare suitable for cutting thin metals, such as aluminum and titanium, and for intricate shapes.

- Standard tipsare versatile and can be used for a wide range of applications.

- Extended tipsare beneficial for cutting in tight spaces or when visibility is limited.

- Shielded tipsare recommended for cutting non-ferrous metals, such as aluminum and copper, to prevent arc wander.

- Swirl tipsare preferred for precision cutting applications, such as cutting stencils or intricate designs.

By understanding the different types of cutting tips and their characteristics, you can select the most appropriate tip for your specific cutting needs, ensuring optimal performance and desired results.

Cutting Parameters

Cutting parameters are crucial for optimizing the performance of any cutting operation. They directly influence the quality, efficiency, and cost of the cut.

Need a hand finding the right cutting tip for your Victor torch? Check out our comprehensive cutting tip chart. It’s packed with all the info you need to make sure you’re using the right tip for the job. And if you’re looking for a compatibility chart for Siemens breakers, we’ve got you covered there too.

Just click here for our handy Siemens breaker compatibility chart. Then come back here for more tips on choosing the perfect cutting tip for your Victor torch.

The key cutting parameters include:

- Cutting speed: The rate at which the cutting tip moves through the material.

- Feed rate: The rate at which the material is fed into the cutting tip.

- Depth of cut: The depth to which the cutting tip penetrates the material.

The optimal cutting parameters depend on the material properties and the type of cutting tip being used. For example, harder materials require lower cutting speeds and higher feed rates, while softer materials require higher cutting speeds and lower feed rates.

Material Properties

The material properties that affect cutting parameters include:

- Hardness: The resistance of the material to deformation.

- Tensile strength: The ability of the material to withstand stretching.

- Ductility: The ability of the material to deform without breaking.

- Thermal conductivity: The ability of the material to conduct heat.

Cutting Tip Type

The type of cutting tip also affects the optimal cutting parameters. Different types of cutting tips have different geometries and coatings that are designed for specific materials and cutting applications.

By considering the material properties and the type of cutting tip being used, it is possible to determine the optimal cutting parameters for a given application. This will help to ensure that the cutting operation is performed efficiently and effectively.

Safety Considerations

Cutting tips are essential tools for various industrial applications, but their improper use can pose significant safety hazards. Understanding and adhering to safety guidelines is crucial to prevent accidents and injuries.

Potential hazards associated with cutting operations include:

- Burns:Contact with hot metal or sparks can cause severe burns.

- Eye injuries:Flying debris or sparks can damage the eyes.

- Inhalation of fumes:Cutting operations generate fumes that can be harmful if inhaled.

- Explosion:Improper handling or storage of cutting tips can lead to explosions.

Proper Handling

To ensure safe handling of cutting tips:

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and respiratory protection.

- Inspect cutting tips regularly for damage or wear.

- Use cutting tips only for their intended purpose.

- Never point a cutting tip at yourself or others.

Storage and Maintenance

Proper storage and maintenance are essential for the safety and longevity of cutting tips:

- Store cutting tips in a dry, well-ventilated area.

- Keep cutting tips away from flammable materials.

- Clean cutting tips regularly to remove debris and prevent clogging.

- Replace damaged or worn cutting tips promptly.

By following these safety guidelines, you can minimize the risks associated with cutting operations and ensure a safe work environment.

Troubleshooting Common Issues: Victor Cutting Tip Chart

When using cutting tips, you may encounter various issues that can affect the quality of your cuts or even pose safety hazards. Understanding the causes and symptoms of these issues is crucial for effective troubleshooting and resolving them promptly.

Identifying Common Issues

Common issues with cutting tips can include:

- Poor cut quality (e.g., rough edges, excessive dross)

- Difficulty in starting or maintaining the cut

- Excessive heat buildup

- Tip clogging or overheating

- Premature tip failure

Advanced Applications

Cutting tips have advanced beyond manual cutting applications and are now integrated into automated cutting systems. These systems leverage computer numerical control (CNC) technology, enabling precise and efficient cutting of complex shapes and designs.

Benefits of Automated Cutting Systems

- Increased precision:CNC systems control the cutting tip’s movement with high accuracy, reducing errors and ensuring consistent results.

- Improved efficiency:Automated systems operate at higher speeds and can work continuously, maximizing productivity.

- Reduced labor costs:Automated cutting systems eliminate the need for manual labor, reducing labor costs and freeing up operators for other tasks.

- Enhanced safety:Automated systems minimize the risk of operator injury by keeping them away from the cutting zone.

Challenges of Automated Cutting Systems

- High initial investment:Automated cutting systems can be expensive to purchase and maintain.

- Training requirements:Operators need to be trained on the specific CNC system and cutting techniques.

- Complexity:Automated cutting systems require regular maintenance and calibration to ensure optimal performance.

Industries Using Advanced Cutting Applications, Victor cutting tip chart

Advanced cutting applications are prevalent in various industries, including:

- Aerospace:Cutting complex aircraft components with precision.

- Automotive:Fabricating automotive parts with high accuracy and efficiency.

- Medical:Producing intricate medical devices and implants.

- Electronics:Cutting precise circuit boards and electronic components.

Our website has become a go-to destination for people who want to create personalized calendars that meet their unique needs. We offer a wide range of customization options, including the ability to add your own images, logos, and branding. Our users appreciate the flexibility and versatility of our calendars, which can be used for a variety of purposes, including personal, educational, and business use.