Introducing the fiber connector types chart, your ultimate resource for understanding the diverse world of fiber optic connectors. From their intricate designs to their specialized applications, this guide unravels the complexities of these essential components, empowering you with the knowledge to make informed choices for your fiber optic systems.

Delve into the fascinating realm of fiber connector types, where each type holds unique characteristics and serves specific purposes. Discover the intricate details of their construction, unravel the mysteries of their performance metrics, and gain insights into the industry standards that govern their design and manufacturing.

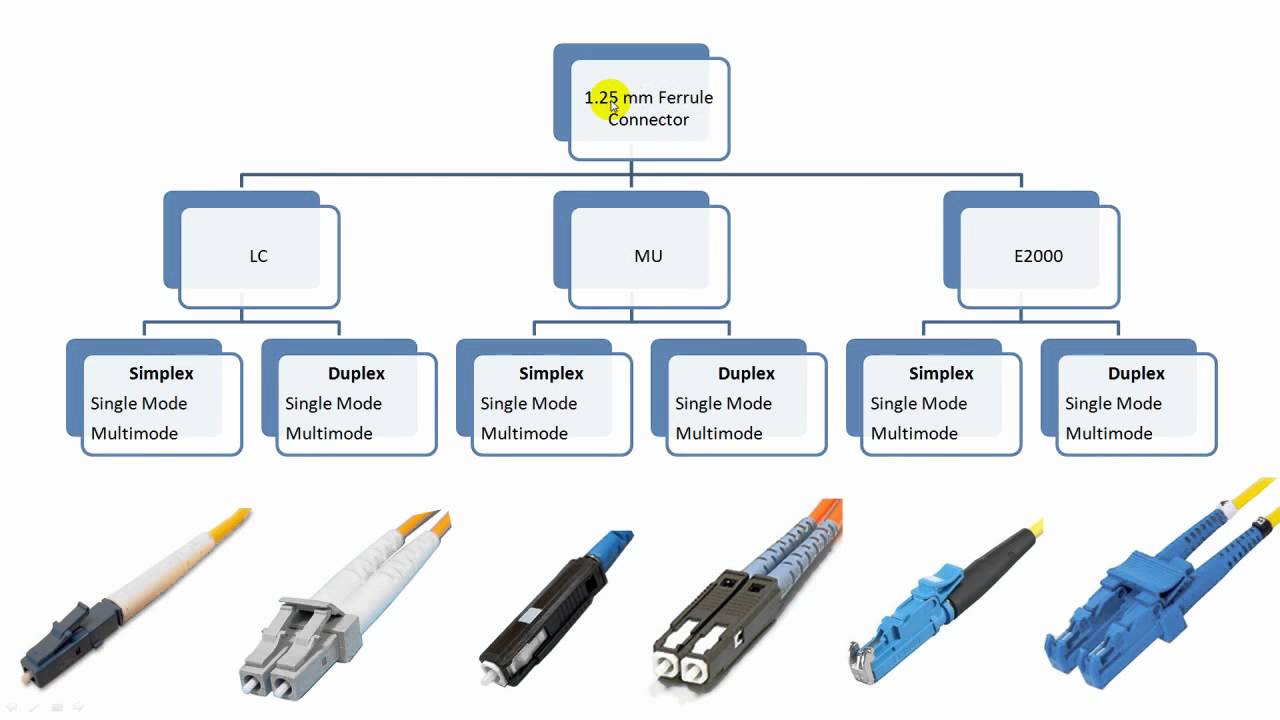

Fiber Connector Types

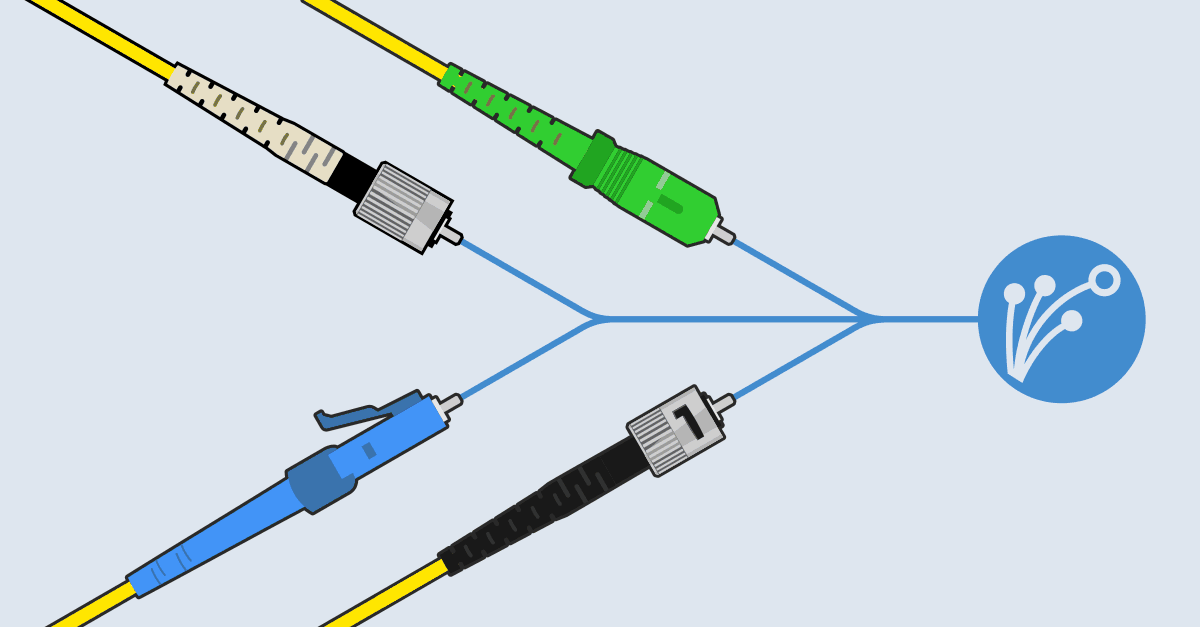

Fiber optic connectors are critical components in fiber optic networks, providing a reliable and efficient means of connecting fiber optic cables and devices. Various types of fiber connectors exist, each with unique characteristics and applications.

When it comes to choosing the right fiber connector for your needs, it’s helpful to have a visual reference to compare different types. That’s where a fiber connector types chart comes in handy. If you’re also interested in exploring color options for your textile projects, check out this comprehensive kona cotton color chart . With its wide range of hues, you’re sure to find the perfect shade for your next creation.

And don’t forget to return to the fiber connector types chart to finalize your connectivity choices.

Common Fiber Connector Types

- SC Connector (Subscriber Connector):A popular connector type known for its simple push-pull locking mechanism. It’s commonly used in telecommunication networks and data centers.

- LC Connector (Lucent Connector):A compact connector with a latching mechanism, making it suitable for high-density applications. It’s widely used in data centers and telecommunication networks.

- FC Connector (Ferrule Connector):A threaded connector type that provides secure connections. It’s often used in industrial and military applications where durability is crucial.

- ST Connector (Straight Tip):An older connector type that uses a bayonet locking mechanism. It’s still used in some legacy applications.

- MTP Connector (Multi-Fiber Push-On):A multi-fiber connector that allows for the simultaneous connection of multiple fibers. It’s commonly used in high-speed data center applications.

Comparison of Fiber Connector Types

The table below compares the specifications of different fiber connector types:

| Connector Type | Interface Type | Ferrule Material | Insertion Loss (dB) | Return Loss (dB) |

|---|---|---|---|---|

| SC | Push-Pull | Zirconia | 0.2 | 45 |

| LC | Latching | Zirconia | 0.1 | 55 |

| FC | Threaded | Stainless Steel | 0.3 | 40 |

| ST | Bayonet | Stainless Steel | 0.5 | 30 |

| MTP | Push-On | Zirconia | 0.15 | 60 |

Fiber Connector Standards

Fiber connector standards play a crucial role in ensuring the interoperability and performance of fiber optic networks. These standards define the physical, mechanical, and optical characteristics of fiber connectors, enabling seamless and reliable connections between different devices and components.

International Standards Organizations

Several international organizations are involved in developing and maintaining fiber connector standards. The most prominent among them are:

- International Electrotechnical Commission (IEC): IEC develops and publishes international standards for electrical, electronic, and related technologies, including fiber optic connectors.

- Telecommunications Industry Association (TIA): TIA is a trade association representing the telecommunications industry in North America. It develops and publishes standards for various aspects of telecommunications, including fiber optic connectors.

Specific Fiber Connector Standards

There are numerous fiber connector standards that have been developed over the years, each designed for specific applications and environments. Some of the most widely used standards include:

- IEC 61754-4: This standard defines the physical dimensions, performance, and test methods for fiber optic connectors used in telecommunications applications.

- TIA-568-C.3: This standard specifies the requirements for fiber optic connectors used in structured cabling systems.

- MIL-PRF-29504: This military standard defines the performance requirements for fiber optic connectors used in military and aerospace applications.

These standards ensure that fiber optic connectors meet specific performance criteria, such as low insertion loss, high return loss, and durability, ensuring reliable and efficient data transmission.

Fiber Connector Manufacturing

The manufacturing of fiber connectors involves a series of precise steps to ensure the performance and reliability of the final product. These steps include the production of individual components, assembly, and quality control.

If you’re interested in learning about the different types of fiber connectors, there’s a handy chart available online. You can also check out the des plaines theater seating chart if you’re planning a night out at the movies. Once you’ve familiarized yourself with the various fiber connector types, you’ll be able to make informed decisions about which ones to use for your specific needs.

The materials used in fiber connector manufacturing vary depending on the type of connector being produced. Common materials include:

- Ferrule:Typically made of ceramic or metal, the ferrule holds the fiber in place and aligns it with the mating connector.

- Housing:The housing provides protection and support for the ferrule and other components.

- Contact:The contact is the part of the connector that makes electrical contact with the mating connector.

Ferrule Manufacturing, Fiber connector types chart

The ferrule is a critical component of a fiber connector, as it ensures the alignment of the fiber cores. The manufacturing process of a ferrule involves:

- Material selection:The material for the ferrule is chosen based on its optical properties, mechanical strength, and durability.

- Precision machining:The ferrule is machined to precise dimensions to ensure proper alignment of the fiber cores.

- Polishing:The ferrule is polished to achieve a smooth surface finish, which minimizes signal loss.

Fiber Connector Testing: Fiber Connector Types Chart

Testing fiber connectors is crucial to ensure they meet industry standards and perform reliably in real-world applications. Various methods are used to test fiber connectors, measuring parameters like insertion loss, return loss, and optical power loss.

Insertion Loss

Insertion loss measures the power loss introduced when a connector is inserted into a fiber optic link. It is expressed in decibels (dB) and should be as low as possible for efficient signal transmission.

Return Loss

Return loss measures the amount of light reflected back towards the source when a signal passes through a connector. High return loss is desirable to minimize signal distortion and reflections.

Optical Power Loss

Optical power loss measures the total power loss experienced by a signal passing through a connector. It includes insertion loss, return loss, and other factors that contribute to signal degradation.

Fiber Connector Applications

Fiber connectors play a crucial role in connecting fiber optic cables and devices, enabling the transmission of light signals over long distances with minimal loss. They find applications in various industries and scenarios.

Data Centers and Telecommunications

In data centers and telecommunications networks, fiber connectors facilitate high-speed data transmission and network connectivity. The use of fiber optic cables with fiber connectors allows for increased bandwidth and reduced latency, making them ideal for supporting the growing demands of data-intensive applications and cloud computing.

Industrial Automation

Fiber connectors are employed in industrial automation systems to connect sensors, actuators, and other devices in harsh environments. Their immunity to electromagnetic interference and ability to transmit data over extended distances make them suitable for industrial applications where reliability and durability are paramount.

Medical and Healthcare

Fiber connectors are used in medical and healthcare settings for various applications, including endoscopy, laser surgery, and medical imaging. They enable the transmission of high-resolution images and data, providing medical professionals with enhanced diagnostic and treatment capabilities.

Aerospace and Defense

In the aerospace and defense industries, fiber connectors are used in aircraft and military systems for secure and reliable data transmission. Their lightweight and rugged construction make them suitable for harsh environments and applications where space and weight constraints are critical.

Advantages and Limitations

Fiber connectors offer several advantages, including:

High bandwidth and low loss

Fiber connectors allow for high-speed data transmission with minimal signal degradation.

EMI immunity

Fiber connectors are immune to electromagnetic interference, making them suitable for use in environments with electrical noise.

Durability

Fiber connectors are designed to withstand harsh conditions, including temperature fluctuations, vibration, and moisture.However, fiber connectors also have some limitations:

Precision alignment

Fiber connectors require precise alignment to ensure optimal signal transmission.

Cost

Fiber connectors can be more expensive than other types of connectors.

Fragility

Fiber connectors can be fragile and require careful handling to avoid damage.

Impact of Connector Type

The choice of fiber connector type can impact the performance and reliability of a fiber optic system. Different connector types have varying characteristics, such as optical performance, insertion loss, and durability. Selecting the appropriate connector type for a specific application is crucial to ensure optimal system performance.

.gallery-container {

display: flex;

flex-wrap: wrap;

gap: 10px;

justify-content: center;

}

.gallery-item {

flex: 0 1 calc(33.33% – 10px); /* Fleksibilitas untuk setiap item galeri */

overflow: hidden; /* Pastikan gambar tidak melebihi batas kotak */

position: relative;

margin-bottom: 20px; /* Margin bawah untuk deskripsi */

}

.gallery-item img {

width: 100%;

height: 200px;

object-fit: cover; /* Gambar akan menutupi area sepenuhnya */

object-position: center; /* Pusatkan gambar */

}

.image-description {

text-align: center; /* Rata tengah deskripsi */

}

@media (max-width: 768px) {

.gallery-item {

flex: 1 1 100%; /* Full width di layar lebih kecil dari 768px */

}

}

Our website has become a go-to destination for people who want to create personalized calendars that meet their unique needs. We offer a wide range of customization options, including the ability to add your own images, logos, and branding. Our users appreciate the flexibility and versatility of our calendars, which can be used for a variety of purposes, including personal, educational, and business use.