Piston chart for goodman – Step into the realm of piston charts for Goodman, a valuable tool for HVAC professionals seeking to optimize system performance. These charts provide a visual representation of system behavior, enabling engineers to identify trends, troubleshoot issues, and enhance overall efficiency.

Delve into the intricate details of Goodman piston charts, their applications, and advanced techniques to unlock the full potential of your HVAC systems.

Piston Chart Overview

A piston chart is a graphical representation that visually depicts the relationship between two or more variables over time. It is particularly useful for tracking the performance of a system or process and identifying trends and patterns.

A piston chart consists of a series of vertical bars, with each bar representing a specific time period. The height of each bar corresponds to the value of the variable being measured. The chart can be used to track multiple variables simultaneously, allowing for easy comparison and analysis.

If you’re looking for a piston chart for Goodman, you’ll find a variety of resources online. However, if you need a quick reference for geometry formulas, you can use a staar geometry formula chart . This chart provides a comprehensive list of formulas for various geometry concepts, including area, volume, and angle measures.

Once you’ve reviewed the formulas, you can return to your piston chart for Goodman and continue working on your project.

Key Components and Structure

- Vertical Bars:Represent the values of the variables being measured over time.

- Time Axis:Displays the time periods being tracked.

- Value Axis:Indicates the range of values being measured.

- Legend:Identifies the different variables being tracked.

Uses of Piston Charts

Piston charts are used in various industries to track and analyze performance metrics, including:

- Manufacturing:Monitoring production output, machine uptime, and quality control.

- Healthcare:Tracking patient outcomes, medication adherence, and hospital readmissions.

- Finance:Analyzing stock prices, market trends, and investment returns.

Goodman Piston Chart: Piston Chart For Goodman

The Goodman piston chart is a graphical representation of the performance of a reciprocating compressor. It is used to analyze and predict system performance, and to troubleshoot problems. The chart is divided into two sections: the suction side and the discharge side.

The suction side of the chart shows the relationship between the suction pressure, the suction temperature, and the compressor displacement. The discharge side of the chart shows the relationship between the discharge pressure, the discharge temperature, and the compressor displacement.

Applications of the Goodman Piston Chart

The Goodman piston chart is used in a variety of applications in the HVAC industry, including:

- Sizing compressors

- Predicting system performance

- Troubleshooting problems

Creating a Goodman Piston Chart

Crafting a Goodman piston chart requires meticulous attention to detail and precision. Follow these steps to ensure accuracy and effectiveness:

Data Selection

Choose relevant and reliable data that aligns with the specific purpose of your piston chart. Consider factors such as sample size, data distribution, and potential outliers.

Piston charts for Goodman AC units can provide valuable insights into the performance of your system. If you’re looking for a comprehensive resource on tide charts in Beaufort, NC, check out this beaufort nc tide chart . Returning to piston charts, they can help you troubleshoot issues, monitor energy consumption, and optimize the efficiency of your Goodman unit.

Parameter Determination

Define the parameters of your chart, including the number of pistons, piston dimensions, and the spacing between them. These parameters will determine the overall shape and characteristics of the chart.

Accuracy and Precision

Ensure the accuracy and precision of your data and calculations. This involves carefully verifying the data, using appropriate statistical methods, and adhering to established best practices.

Interpreting a Goodman Piston Chart

Interpreting a Goodman piston chart involves understanding the different sections and symbols and identifying key trends and patterns. However, it’s essential to be aware of the limitations and potential pitfalls to ensure accurate analysis.

Understanding Sections and Symbols

- Data Table:Contains numerical data representing measurements taken from the piston.

- Graph:A visual representation of the data, showing the piston’s displacement over time.

- Indicator Diagram:A graph that plots the piston’s pressure against its volume, providing insights into the engine’s performance.

- Symbols:Various symbols are used to represent specific events, such as the top dead center (TDC) and bottom dead center (BDC) of the piston.

Identifying Trends and Patterns

By analyzing the graph and indicator diagram, you can identify trends and patterns that indicate the engine’s health and performance. For instance, a consistent sinusoidal wave in the graph suggests a well-functioning engine, while irregularities may indicate potential issues.

Limitations and Pitfalls

- Accuracy of Data:The accuracy of the piston chart depends on the accuracy of the measurements taken.

- Interpretation Subjectivity:Different individuals may interpret the same piston chart differently, leading to varying conclusions.

- Contextual Factors:External factors, such as engine speed and load, can influence the piston chart’s interpretation.

Applications of Goodman Piston Charts

Goodman piston charts are valuable tools for HVAC technicians and engineers, providing insights into the performance and efficiency of refrigeration systems.

They are commonly used for troubleshooting, system optimization, and performance monitoring.

Troubleshooting

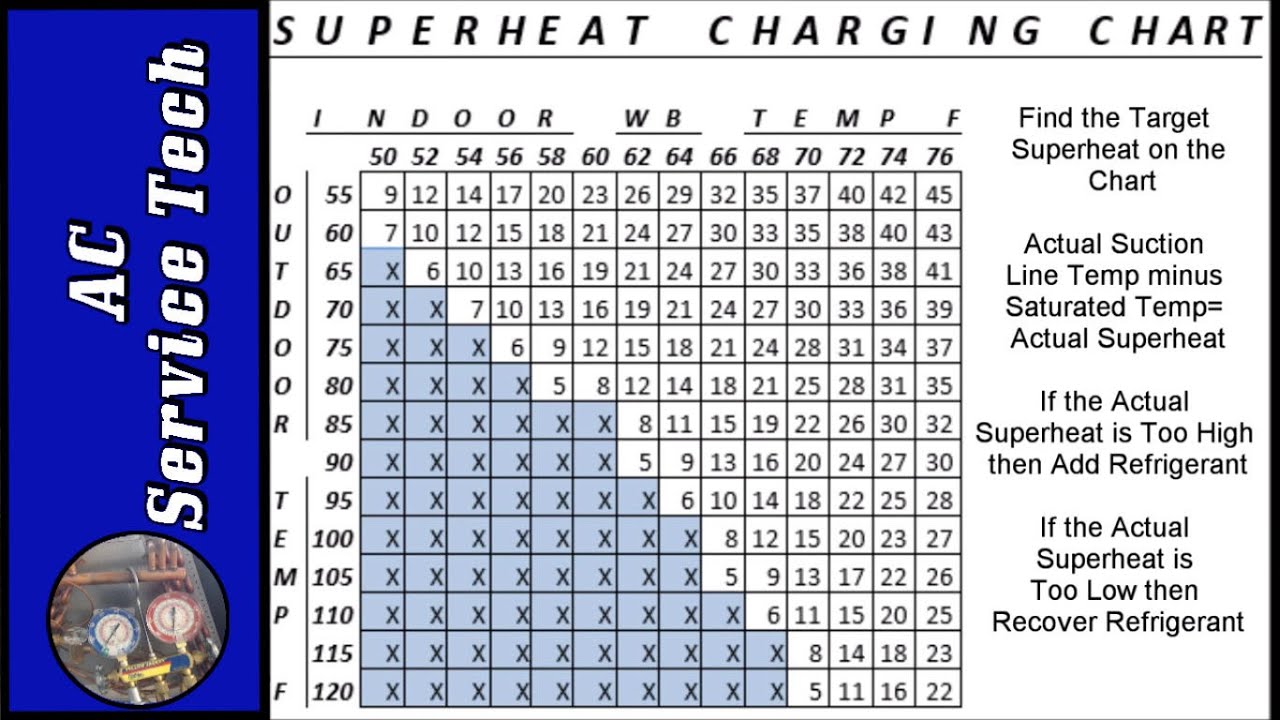

Piston charts can help identify and diagnose problems within a refrigeration system. By comparing actual operating conditions to the ideal conditions on the chart, technicians can pinpoint potential issues, such as refrigerant leaks, compressor problems, or faulty expansion devices.

System Optimization

Piston charts can be used to optimize the performance of a refrigeration system. By adjusting the operating conditions, such as the evaporator and condenser pressures, technicians can improve the system’s efficiency and capacity.

Performance Monitoring, Piston chart for goodman

Piston charts can be used to monitor the performance of a refrigeration system over time. By tracking the operating conditions on the chart, technicians can identify any changes or trends that may indicate potential problems or areas for improvement.

Examples

Here are some examples of how piston charts have been used to improve HVAC system efficiency and reliability:

- In one case, a piston chart was used to identify a refrigerant leak in a commercial refrigeration system. The leak was repaired, resulting in a significant improvement in system efficiency.

- In another case, a piston chart was used to optimize the operating conditions of a residential air conditioning system. The optimization resulted in a 10% reduction in energy consumption.

- In a third case, a piston chart was used to monitor the performance of a large industrial refrigeration system. The monitoring helped identify a gradual decline in system efficiency, which was traced to a faulty compressor. The compressor was replaced, restoring the system to its original performance.

Advanced Techniques for Goodman Piston Charts

Advanced techniques for Goodman piston charts extend their utility beyond basic analysis. These techniques involve statistical methods and modeling to extract deeper insights, enabling predictive maintenance and system diagnostics.

Using Statistical Methods

Statistical methods can be applied to Goodman piston chart data to identify patterns, trends, and correlations. For example, regression analysis can be used to model the relationship between piston displacement and system parameters such as pressure and temperature. This model can then be used to predict system behavior under different operating conditions.

Modeling Techniques

Modeling techniques, such as finite element analysis (FEA), can be used to create virtual models of piston systems. These models can be used to simulate system behavior and predict performance under various conditions. This can help identify potential failure modes and optimize system design.

Predictive Maintenance and System Diagnostics

Goodman piston charts can be used for predictive maintenance by monitoring system parameters and identifying trends that may indicate potential problems. For example, a sudden increase in piston displacement could indicate a problem with the piston or cylinder. By tracking these trends, maintenance can be scheduled before a failure occurs.

Our website has become a go-to destination for people who want to create personalized calendars that meet their unique needs. We offer a wide range of customization options, including the ability to add your own images, logos, and branding. Our users appreciate the flexibility and versatility of our calendars, which can be used for a variety of purposes, including personal, educational, and business use.