Navigating the world of rubber stoppers just got easier with our comprehensive rubber stopper size chart. Delve into the fascinating realm of these versatile components, exploring their diverse applications, types, and essential parameters.

From scientific laboratories to industrial settings, rubber stoppers play a crucial role in ensuring secure closures and preventing contamination. Our guide empowers you to make informed decisions when selecting the perfect stopper size for your specific needs.

Overview of Rubber Stopper Size Charts

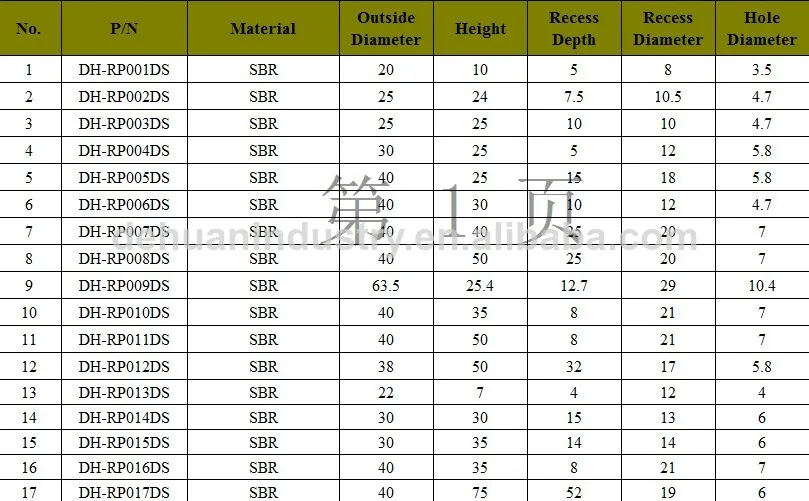

Rubber stopper size charts are essential tools for selecting the appropriate stopper size for various applications. They provide a comprehensive overview of the dimensions, shapes, and specifications of different rubber stoppers.

These charts are widely used in industries such as laboratory research, pharmaceutical manufacturing, and biotechnology. They enable users to identify the ideal stopper size based on the container opening, required seal strength, and specific application requirements.

If you’re looking for a comprehensive rubber stopper size chart, I recommend checking out this handy resource. And while you’re at it, don’t forget to take a peek at the rain bird 1800 nozzle chart as well. It’s a great tool for finding the right nozzle for your irrigation system.

Returning to the rubber stopper size chart, remember that accurate measurements are crucial for a proper fit. So, be sure to consult the chart carefully before making any purchases.

Applications of Rubber Stopper Size Charts

- Selecting the correct stopper size for test tubes, flasks, and other laboratory glassware

- Determining the appropriate stopper size for vials, bottles, and containers used in pharmaceutical manufacturing

- Identifying the ideal stopper size for bioreactors, fermenters, and other biotechnology equipment

Types of Rubber Stoppers

Rubber stoppers are available in a wide range of shapes, materials, and sizes to meet the diverse needs of various applications.

Based on Shape

- Conical:Tapered shape with a narrow tip and a wider base, ideal for sealing narrow openings.

- Cylindrical:Straight-sided with a uniform diameter, commonly used in flasks, test tubes, and bottles.

- Bulb:Round or oval shape with a hollow interior, designed for applications where flexibility is required.

- Flat-top:Square or rectangular shape with a flat top, suitable for sealing large openings.

Based on Material

- Natural Rubber:Derived from the sap of rubber trees, known for its elasticity, durability, and resistance to chemicals.

- Synthetic Rubber:Made from petroleum-based materials, offering improved chemical resistance, heat resistance, and aging resistance.

- Silicone Rubber:A high-performance material with excellent heat resistance, flexibility, and biocompatibility.

- Viton Rubber:A fluorocarbon-based material with exceptional resistance to harsh chemicals and solvents.

Based on Size

Rubber stoppers are available in a range of sizes, typically measured in millimeters or inches, to fit different openings and applications.

Size Measurement Parameters

Rubber stopper sizes are determined by various parameters. Understanding these parameters is crucial for selecting the appropriate stopper for specific applications.

If you’re looking for a rubber stopper size chart, there are many resources available online. But if you’re also interested in finding a portland memorial coliseum seating chart, you can find one here: portland memorial coliseum seating chart . Once you’ve found the right size rubber stopper, you can use it to seal a variety of containers, including bottles, jars, and test tubes.

The key parameters used to measure rubber stopper sizes include:

Diameter

The diameter of a rubber stopper refers to the width of its circular base. It is typically measured in millimeters (mm). The diameter determines the size of the opening the stopper can seal.

Height

The height of a rubber stopper refers to its vertical measurement from the base to the top. It is also measured in millimeters (mm). The height determines the depth of the opening the stopper can seal.

Bore Size

The bore size of a rubber stopper refers to the diameter of the hole or opening in the center of the stopper. It is also measured in millimeters (mm). The bore size determines the size of the tube or fitting that can be inserted into the stopper.

Reading and Interpreting Size Charts

Understanding rubber stopper size charts is crucial for selecting the correct stopper for your application. These charts typically provide detailed information about the dimensions and specifications of various stopper sizes.

Using Tables or Visual Aids

Size charts often use tables or other visual aids to simplify interpretation. Each row or column in a table represents a specific stopper size, with the corresponding dimensions listed in millimeters or other relevant units.

- Top Row/Column: Typically indicates the stopper size designation, such as #00, #5, or #10.

- Subsequent Rows/Columns: List the dimensions of the stopper, including the top diameter, bottom diameter, height, and any other relevant measurements.

By carefully examining these tables and visual aids, you can easily identify the stopper size that meets your specific requirements.

Factors to Consider When Selecting Rubber Stoppers: Rubber Stopper Size Chart

Selecting the appropriate rubber stopper size is crucial to ensure proper functionality and safety in various applications. Here are key factors to consider:

Compatibility

- Chemical Compatibility:Ensure the stopper material is compatible with the fluids or chemicals it will come into contact with to prevent reactions or contamination.

- Temperature Range:Consider the temperature range in which the stopper will be used, as rubber materials have varying temperature resistance.

- Pressure Tolerance:Determine the pressure rating of the stopper to ensure it can withstand the expected pressure in the application.

Functionality

- Size and Shape:Choose a stopper that fits snugly into the opening to create a leak-proof seal. Consider the shape of the opening and the stopper’s design (e.g., conical, cylindrical).

- Purpose:Determine the intended use of the stopper, such as sealing, venting, or sampling. Different stoppers are designed for specific functions.

- Insertion and Removal:Consider the ease of inserting and removing the stopper, especially if frequent access is required.

Safety

- Material Quality:Select stoppers made from high-quality materials that meet industry standards to ensure reliability and durability.

- Certifications:Look for stoppers that comply with relevant certifications, such as USP Class VI or FDA-approved, for applications involving medical or pharmaceutical products.

- Toxicity:Choose stoppers that are non-toxic and do not leach harmful substances into the environment or fluids.

Customization Options

Custom rubber stopper sizes are available to cater to specific laboratory or industrial requirements that fall outside of standard dimensions. This customization allows for precise fitting and optimal performance in unique applications.

To specify custom sizes, it is necessary to provide detailed dimensions, including the diameter, height, and any special features or configurations required. The supplier will then assess the feasibility of producing the custom stoppers and provide a lead time estimate.

Lead times may vary depending on the complexity of the design and the production schedule of the supplier.

Best Practices for Using Rubber Stoppers

Rubber stoppers are versatile laboratory consumables, but their integrity and effectiveness can be compromised by improper handling and storage. Here are some best practices to ensure optimal performance and longevity:

Handling

- Handle stoppers with clean, dry hands or gloves to prevent contamination.

- Avoid excessive force or twisting, as it can damage the stopper or the container it seals.

- Use appropriate tools, such as a stopper puller, to remove stoppers from containers safely.

Storage, Rubber stopper size chart

- Store stoppers in a cool, dry place away from direct sunlight and heat sources.

- Keep stoppers in their original packaging or a clean, sealed container to prevent dust and contamination.

- Avoid storing stoppers in contact with other materials, as they may absorb odors or chemicals.

Usage

- Ensure the stopper fits snugly into the container to create an airtight seal.

- Do not overtighten stoppers, as it can cause damage or leakage.

- If a stopper becomes contaminated, discard it and use a new one.

- Regularly inspect stoppers for signs of damage or wear, and replace them as necessary.

Industry Standards and Regulations

Rubber stopper size charts are subject to various industry standards and regulations to ensure consistency, quality, and compliance.

These standards define specific requirements for size measurements, materials, and testing procedures to ensure the reliability and accuracy of rubber stoppers used in various applications.

Compliance Requirements

- ISO 3833: This international standard establishes general specifications for rubber stoppers and caps, including dimensions, tolerances, and performance requirements.

- ASTM D415: This American Society for Testing and Materials (ASTM) standard covers the dimensions and tolerances of rubber stoppers for laboratory and industrial applications.

- USP 31: This United States Pharmacopeia (USP) standard provides guidelines for the design and performance of rubber stoppers used in pharmaceutical packaging and delivery systems.

Testing Procedures

- Tensile strength testing: Measures the force required to break a rubber stopper.

- Elongation at break testing: Determines the amount of stretching a rubber stopper can withstand before breaking.

- Compression set testing: Assesses the ability of a rubber stopper to recover its original shape after being compressed.

- Leak testing: Ensures that rubber stoppers can effectively seal containers and prevent leakage.

Our website has become a go-to destination for people who want to create personalized calendars that meet their unique needs. We offer a wide range of customization options, including the ability to add your own images, logos, and branding. Our users appreciate the flexibility and versatility of our calendars, which can be used for a variety of purposes, including personal, educational, and business use.