In the realm of industrial machinery, the humble V belt plays a pivotal role in transmitting power from one shaft to another. To ensure optimal performance, selecting the correct V belt size is paramount. This guide delves into the intricacies of V belt size chart conversion, empowering you with the knowledge to make informed decisions and keep your machines running smoothly.

From understanding the different types of V belts and their applications to mastering the conversion methods and formulas, this comprehensive resource will equip you with all the necessary tools to navigate the world of V belt size conversion with confidence.

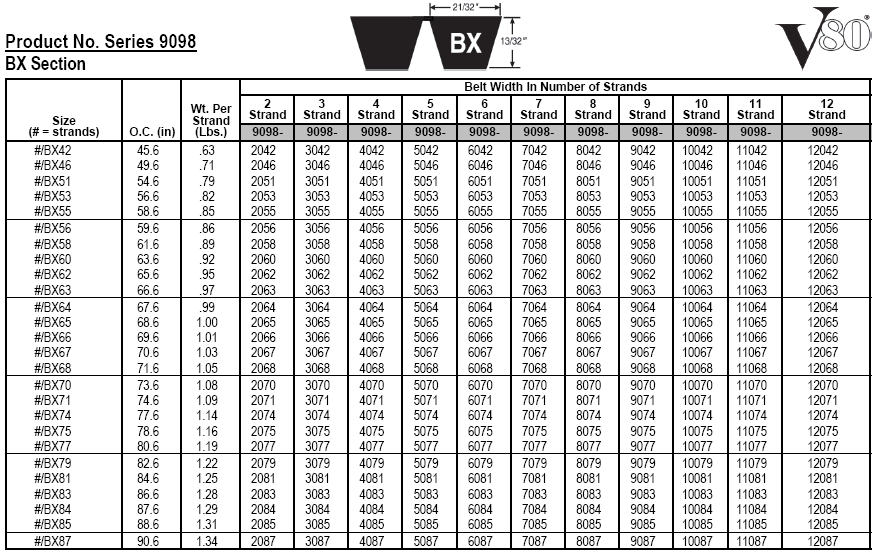

V Belt Size Conversion Chart Overview

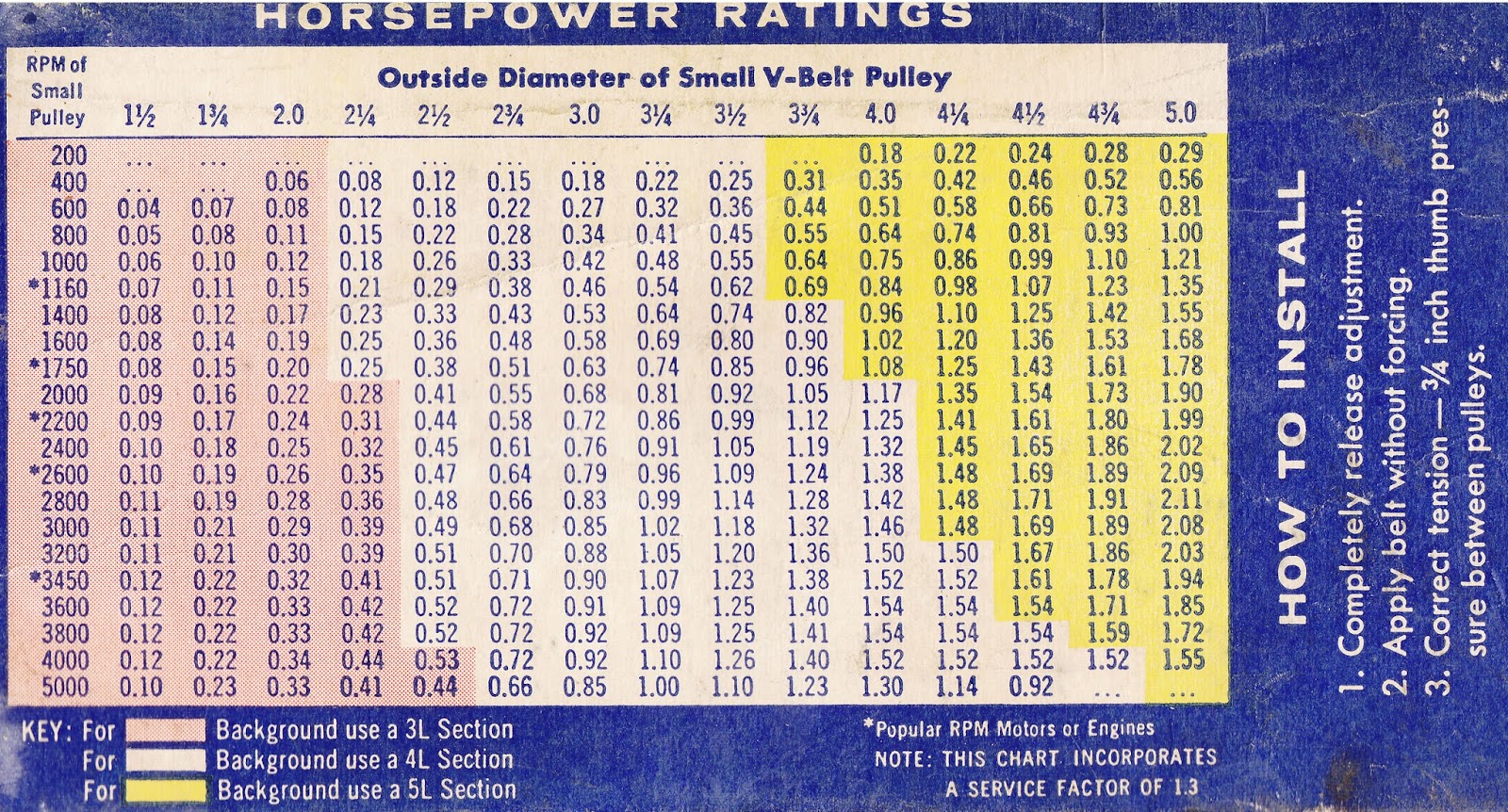

A V-belt size conversion chart is a tool used to determine the correct size of a V-belt for a specific application. V-belts are used in a wide range of industrial and automotive applications, and it is important to use the correct size belt to ensure proper operation and longevity.

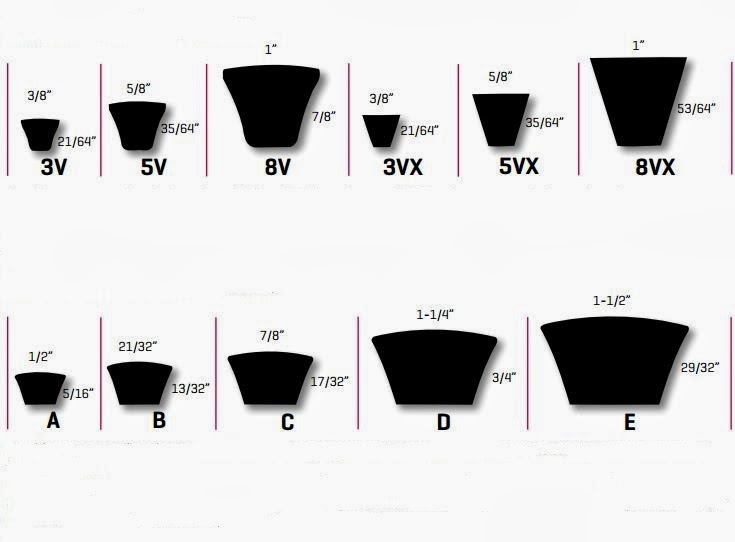

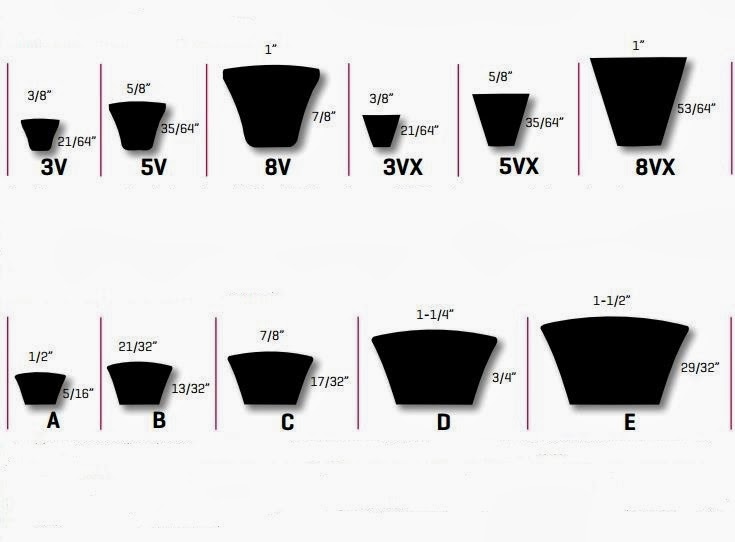

There are different types of V-belts, each with its own unique characteristics and applications. Some of the most common types of V-belts include:

- Classical V-belts: These are the most common type of V-belt and are used in a wide range of applications. They are characterized by their trapezoidal cross-section and are available in a variety of sizes.

- Narrow V-belts: These belts are similar to classical V-belts, but they have a narrower cross-section. This makes them more flexible and better suited for applications where space is limited.

- Banded V-belts: These belts are made up of multiple V-belts that are bonded together. This gives them a higher load-carrying capacity than single V-belts.

- Cogged V-belts: These belts have teeth on the inside surface that mesh with the pulleys. This provides a positive drive and prevents slippage.

When selecting a V-belt, it is important to consider the following factors:

- The type of V-belt required for the application

- The length of the belt

- The width of the belt

- The thickness of the belt

A V-belt size conversion chart can be used to determine the correct size belt for a specific application. The chart will typically list the different types of V-belts, their dimensions, and their applications.

To use a V-belt size conversion chart, simply find the type of V-belt required for the application and then locate the corresponding dimensions in the chart. Once the dimensions have been determined, the correct size belt can be selected.

For a quick conversion of v belt sizes, check out the v belt size chart conversion tool. If you’re looking for a different kind of chart, check out the walton arts center seating chart . This interactive chart will help you find the best seats for your next performance.

Back to v belt size conversion, remember to consider the length, width, and angle of the belt for an accurate conversion.

V Belt Sizing Parameters

To determine the correct size of a v belt, several key parameters need to be considered. These parameters include length, width, and thickness, and they all play a crucial role in ensuring the belt operates efficiently and provides the desired performance.

Determining the correct V-belt size is crucial for optimal performance. Utilize a comprehensive V belt size chart conversion tool to ensure proper fit. If you’re planning a relaxing getaway, consider the serene ambiance of charter club resort naples . Its luxurious amenities and picturesque surroundings offer the perfect escape.

Upon your return, revisit the V belt size chart conversion to finalize your belt selection, ensuring smooth operation of your machinery.

The relationship between these parameters is interdependent. The length of the belt is determined by the distance between the pulleys it connects, while the width and thickness are determined by the power transmission requirements and the specific application.

Length

- The length of a v belt is measured in inches or millimeters and is typically represented by the letter “L”.

- It is crucial to ensure the belt is the correct length to avoid slippage or excessive tension.

- Too short a belt can cause premature failure, while too long a belt can lead to reduced efficiency and increased wear.

Width

- The width of a v belt is measured in inches or millimeters and is typically represented by the letter “W”.

- The width of the belt determines its power transmission capacity.

- A wider belt can transmit more power than a narrower belt.

Thickness, V belt size chart conversion

- The thickness of a v belt is measured in inches or millimeters and is typically represented by the letter “T”.

- The thickness of the belt determines its flexibility and durability.

- A thicker belt is more durable and can withstand higher loads, but it is also less flexible.

| Parameter | Measurement | Description |

|---|---|---|

| Length | Inches or millimeters | Distance between the pulleys |

| Width | Inches or millimeters | Power transmission capacity |

| Thickness | Inches or millimeters | Flexibility and durability |

Industry Standards and Specifications

The v belt industry follows several standards and specifications to ensure consistency and quality in v belt sizing. These standards are developed and maintained by various organizations, including the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI).

These standards provide guidelines for the dimensions, tolerances, and performance characteristics of v belts. They also establish common terminology and testing methods to facilitate communication and comparison between different manufacturers.

ISO Standards

ISO 4183:2016 is the primary international standard for v belts. It specifies the dimensions, tolerances, and performance requirements for classical v belts, wedge v belts, and narrow v belts.

ANSI Standards

ANSI/RMA IP-22:2018 is the American standard for v belts. It covers the same aspects as ISO 4183, but also includes additional requirements for v belts used in automotive applications.

Conversion Methods and Formulas: V Belt Size Chart Conversion

Converting between different V belt sizing systems requires understanding the key parameters and formulas used in each system. This section provides step-by-step instructions on how to convert between the most common V belt sizing systems.

Step-by-Step Conversion Process

1.

-*Identify the original sizing system

Determine the system used to specify the V belt size, such as inches, millimeters, or the manufacturer’s part number.

- 2.

- 3.

- 4.

-*Convert to a common unit

Convert the V belt size to a common unit, such as inches or millimeters.

-*Apply the conversion formula

Use the appropriate conversion formula to convert the V belt size from the common unit to the desired unit.

-*Round the result

Round the converted V belt size to the nearest standard size available.

Conversion Formulas

The following formulas are commonly used for V belt size conversion:

-*Inches to millimeters

mm = in x 25.4

-*Millimeters to inches

in = mm / 25.4

-*Manufacturer’s part number to inches

Refer to the manufacturer’s catalog for the corresponding inch size.

-*Inches to manufacturer’s part number

Refer to the manufacturer’s catalog for the corresponding part number.

Conversion Table

The following table provides a quick reference for converting between common V belt sizing systems:| Original Unit | Conversion Factor | Converted Unit ||—|—|—|| Inches | x 25.4 | Millimeters || Millimeters | / 25.4 | Inches || Manufacturer’s Part Number | Refer to catalog | Inches || Inches | Refer to catalog | Manufacturer’s Part Number |

Applications and Considerations

V belt size conversion is essential in various applications involving power transmission systems. Understanding the factors to consider when selecting a v belt is crucial to ensure efficient operation and prevent premature failure.

Factors to consider include the power to be transmitted, speed ratio, center distance between pulleys, and environmental conditions. The correct v belt size ensures proper engagement with the pulleys, minimizing slippage and maximizing power transmission efficiency.

Applications of V Belt Size Conversion

- Industrial machinery: V belts are widely used in industrial settings to transmit power from motors to driven equipment, such as pumps, compressors, and conveyors.

- Automotive applications: V belts are employed in vehicles to drive accessories like alternators, power steering pumps, and air conditioning compressors.

- Agricultural equipment: V belts play a vital role in powering agricultural machinery, including tractors, combines, and irrigation systems.

.gallery-container {

display: flex;

flex-wrap: wrap;

gap: 10px;

justify-content: center;

}

.gallery-item {

flex: 0 1 calc(33.33% – 10px); /* Fleksibilitas untuk setiap item galeri */

overflow: hidden; /* Pastikan gambar tidak melebihi batas kotak */

position: relative;

margin-bottom: 20px; /* Margin bawah untuk deskripsi */

}

.gallery-item img {

width: 100%;

height: 200px;

object-fit: cover; /* Gambar akan menutupi area sepenuhnya */

object-position: center; /* Pusatkan gambar */

}

.image-description {

text-align: center; /* Rata tengah deskripsi */

}

@media (max-width: 768px) {

.gallery-item {

flex: 1 1 100%; /* Full width di layar lebih kecil dari 768px */

}

}

Our website has become a go-to destination for people who want to create personalized calendars that meet their unique needs. We offer a wide range of customization options, including the ability to add your own images, logos, and branding. Our users appreciate the flexibility and versatility of our calendars, which can be used for a variety of purposes, including personal, educational, and business use.